It’s true, melamine and laminate are used in kitchen cabinetry as a cost-effective finish. But just because they’re both cost-effective doesn’t mean they look cheap. Here is a break down of the difference between the two.

- Melamine pre-finished board is manufactured using resin-impregnated decorative paper. This paper, or film, is glued to both sides of an MDF or particleboard sheet under heat and pressure. It’s generally used for vertical surfaces, such as doors, drawer fronts and end panels.

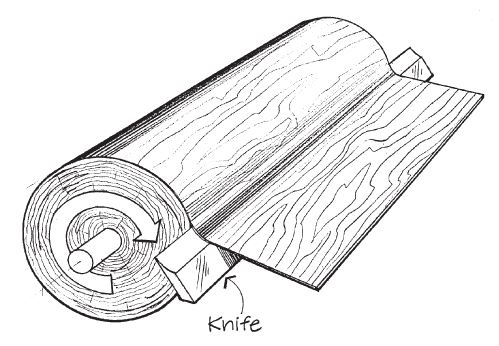

- Laminate is used for horizontal surfaces such as benchtops and tabletops and is the most popular option in kitchen bench tops. Laminate is formed under extreme pressure and heat into a thin layer. This is then glued to raw chipboard or MDF. It can also be used in vertical applications (such as curved paneling) and has a higher resistance to impact, making it more suitable for high traffic areas.

Both materials come in a number of finishes. They also mimic real timber and stone at a fraction of the cost, without sacrificing style. With the advancement in material technology, we are now seeing extremely realistic timber-grain finishes which look just like the real thing. These once “cheap” looking materials have now become a desirable end product, used from small domestic renovation to large architectural projects. Check out Polytec’s “WoodMatte” range here for their realistic timber grain finishes. The possibilities are endless!

Polytec’s entire Melamine Doors and Panel colour selection can be found here:

Polytec’s entire Bench Top and Laminate colour selections can be found here:

And most importantly, Polytec board is manufactured here right in Australia!